It’s not just a superior product.

It’s a superior process.

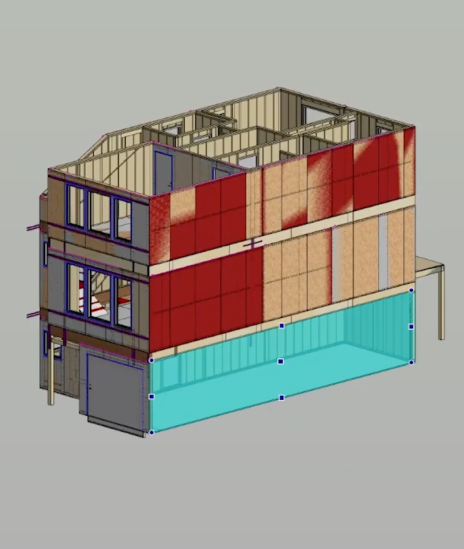

Your project is supported by the best design services in the industry. VBC’s shop drawing and engineering team in Monaghan, Ireland has a deep pool of trained designers with decades of experience in panels.

Our Product

VBC provides the full package to offsite as much of the process as possible. On delivery, your components are complete with blocking and hardware, which means your panels arrive finished.

- Sheer Walls

- Non-Sheer Walls

- Floor Cassettes

- Prefabricated Stairs

- Prefabricated Landings

- All the loose lumber needed to finish the job

Our Process

VBC takes your drawings and specifications and converts them into a digital 3-D model that drives automated manufacturing. In doing so, we can deliver a faster, cleaner, and more consistent product.

- Pre Construction

- Design and Engineering

- Off-Site Manufacturing

- Delivery

- On-Site Assembly

- Finishing